0

bedrooms within easy reach

0

minutes from Dublin airport

0

events held to date

0

awards won for outstanding events

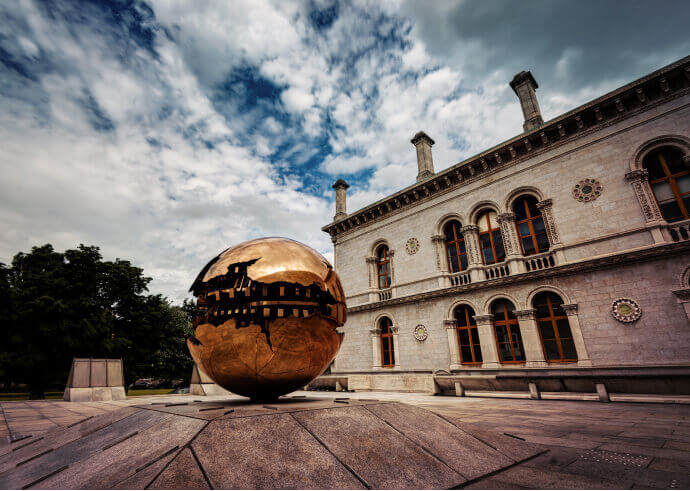

A venue for all

A venue for all

Our Clients

Case Studies

Plan your event

Ideal for...

Discover Dublin

From fun things to do, to top restaurants and bars and events guide.